workinghard

Member

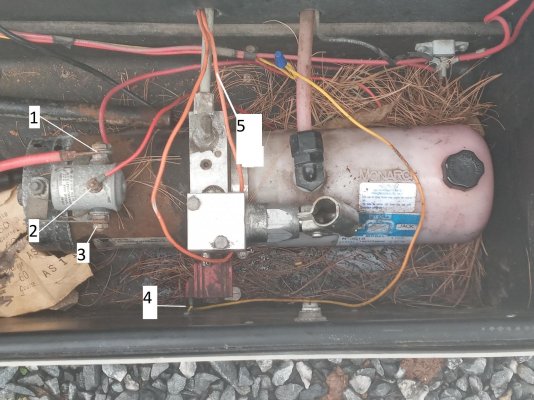

I torqued the frame, and am trying to figure out if I damaged my trailer beyond repair. The lift system safety bar is seized right now. I am living in it full time and don't have a lot of funds, but need to move ASAP.

Heres the back story:

I go some bad advice, and "help" from someone who torqued the bottom of my trailer by attempting to level it via the stabilizing jacks.

He broke 3 of the 4 jacks, and got to the point where the bottom half of the door would not open at all before I told him to stop, and raised the remaining jack.

I then paid a professional to move the trailer back and forth while I put leveling blocks of pressure treated wood under the tires. It was perfectly level when he left, but has settled some.

After about a week, I noticed that the safety bar release cable seemed stuck (when I pull on it, it feels like it is welded in place)

I have been living full time in it, parked, for 2 1/3 months with no stabilizing jacks, and am just now getting the finances together to buy stabilizer jacks.

Do y'all think that after I put new stabilizing jacks under it, that I am going to be able to get this straightened out so I can raise and lower the top? Should I just cut my losses and not spend the money on the stabilizing jacks?

Heres the back story:

I go some bad advice, and "help" from someone who torqued the bottom of my trailer by attempting to level it via the stabilizing jacks.

He broke 3 of the 4 jacks, and got to the point where the bottom half of the door would not open at all before I told him to stop, and raised the remaining jack.

I then paid a professional to move the trailer back and forth while I put leveling blocks of pressure treated wood under the tires. It was perfectly level when he left, but has settled some.

After about a week, I noticed that the safety bar release cable seemed stuck (when I pull on it, it feels like it is welded in place)

I have been living full time in it, parked, for 2 1/3 months with no stabilizing jacks, and am just now getting the finances together to buy stabilizer jacks.

Do y'all think that after I put new stabilizing jacks under it, that I am going to be able to get this straightened out so I can raise and lower the top? Should I just cut my losses and not spend the money on the stabilizing jacks?