Interesting! I'm looking at your thread on my desktop, using Firefox and I see ALL the pictures. I must have an add-on in my notepad version that kills yours, but not others!

At the risk of my life, I've got pictures here. Since the outbreak of Covid, I have done nothing with my trailer and it has been covered since last fall. When I pulled up the cover, so I could raise the top, I found, to my horror, a 4" wide wasp nest inside it with 10 or more wasps in residence. After running for my life, and not being stung (I must be living virtuously), I returned with wasp spray that I used up trying to kill all the critters. They must be tougher than normal - I knocked some of them down but they were able to then fly away! There are still five or more interested in the area where the nest was, and, I MAY have another nest under the front of the trailer.

However, as amusing as this is, it doesn't help your problem, so here are the promised pictures. The first two show the locations of the front and rear outriggers and I lied last night about their position. They are very near the front and rear of the trailer - against the front and rear cross frame actually. You can see the two halves of the hockey puck I used on the outriggers and the rectangular mark across them is where the top sits on them. These have been in place for about 6 years I think and you can see there is some deterioration. I attached them to the outriggers using two of the trailer screws each. The black screws were the originals. The original pads were not placed well - the top rested on the inside edge of them.

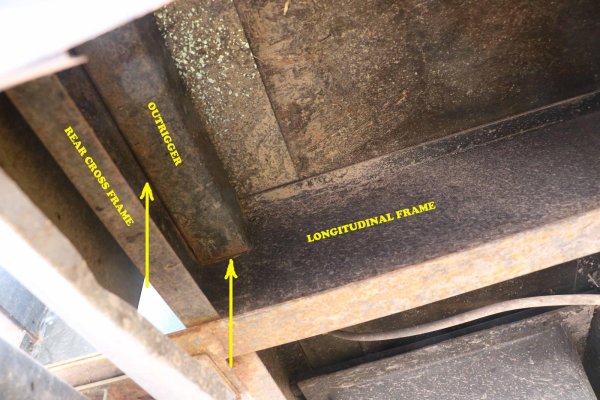

The third picture shows the underside of the rear of my trailer where the outrigger is attached. The two arrows point to joints I can see, and there's no evidence of a weld there. I'm guessing the outrigger is bolted to the rear cross frame member. The outrigger does NOT extend through the longitudinal frame.

To add an outrigger here, using bolts, the skirting would have to be removed. I think it might be easier to weld one in place.

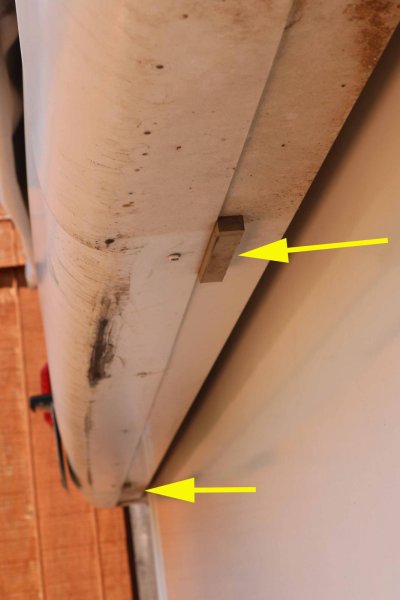

The last two pictures show the pads that are on the top half. The first of these shows the two along the rear end indicated by the arrows (the front end is similar). They show very little deformation, indicating they do not contribute to the support of the top when it is lowered. There are NO corresponding pads on the rear bumper or its supports and there is nothing over the top of the battery box at the front either. The top half of my trailer is not supported at the ends!

The upper pad in the last picture (at the arrow) mates with the outrigger pad. It is quite deformed, showing there is a lot of weight carried here. The upper pads at the other side corners look the same.

So, in my opinion, you could eliminate the stress at the top half of your trailer with a similar outrigger placement. As I said though, if your outrigger is midway along the top, it might work if you could get all the load on it.

- Jack