DennisB-HILO

Advanced Member

hello, I posted this question in the introduce yourself section and realized I should put it in the proper section of this forum so, at the risk of redundency..here goes-

I recently bought a 2008 1508t which we are really enjoying. It came with no installed jacks.

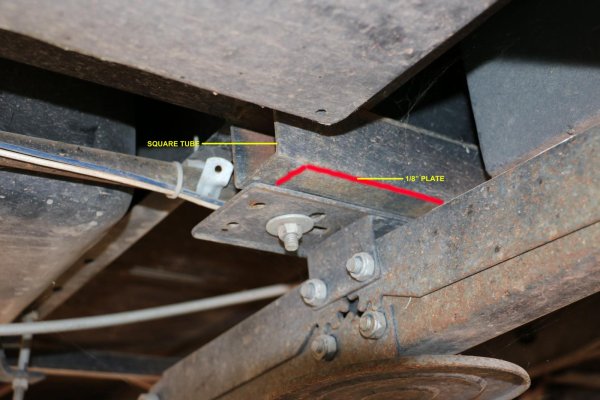

I got some scissor jacks and when I climbed underneath the trailer and held the attach plate of the jack in place against the frame, it was obvious that they would not work.

the sheetmetal shrouds that make up the bottom edge of the trailer extend further down than the height of the collapsed jack. So the nut you turn to activate the jack would be pretty hard to get at.(about 2.5 inches above the bottom of the shroud)

The jack collapses to a 4 inch height and the bottom of the shroud is about 4.5 inches.

I guess I could cut a hole in the shroud material that would allow access to the activating nut of the jack but I am reluctant to hack away on this nice little trailer if there was some other means of installing the jacks or some other type of installed jack that I could use.

some kind of a large shim material could be used to drop the height of the jack but it would have to be about 3 inches or so thick and that doesnt seem like a good idea.(clearance and all)

Does anyone have and suggestions?

I recently bought a 2008 1508t which we are really enjoying. It came with no installed jacks.

I got some scissor jacks and when I climbed underneath the trailer and held the attach plate of the jack in place against the frame, it was obvious that they would not work.

the sheetmetal shrouds that make up the bottom edge of the trailer extend further down than the height of the collapsed jack. So the nut you turn to activate the jack would be pretty hard to get at.(about 2.5 inches above the bottom of the shroud)

The jack collapses to a 4 inch height and the bottom of the shroud is about 4.5 inches.

I guess I could cut a hole in the shroud material that would allow access to the activating nut of the jack but I am reluctant to hack away on this nice little trailer if there was some other means of installing the jacks or some other type of installed jack that I could use.

some kind of a large shim material could be used to drop the height of the jack but it would have to be about 3 inches or so thick and that doesnt seem like a good idea.(clearance and all)

Does anyone have and suggestions?