the For me I have installed the caps with grease fittings but in any case I do not over grease them because if I did i was informed could get onto the brakes.

For those wondering how this would all transpire I will attempt to explain it.

There are two different types of axle caps with grease zerks on them.

One cap is plain with just a grease zerk on the face of it.

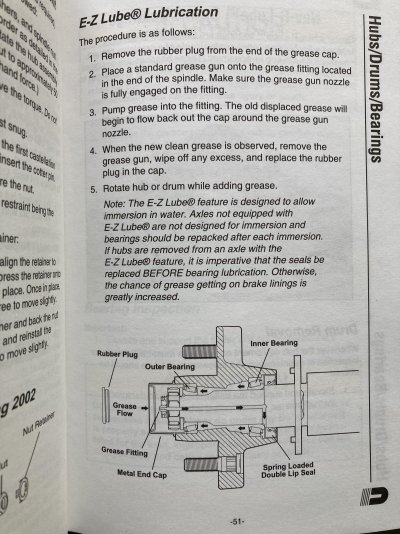

The other cap has a type of spring loaded plunger in it. This is usually found on boat trailers where the pressure from the spring and grease will usually prevent water from getting into the bearings and hub.

You can also buy hubs that have the grease zerk made right into the casting of the hub itself. This one will place/shoot the grease in between the two bearings.

Both of the cap-grease zerks have a few downfalls. (Actually all three have issues.)

The first major issue with the cap method is that you pump enough grease into the cap and it may pass through the outer bearing but typically will not reach the inner bearing. As well as the hub-zerk method, you pump grease in there, was it enough, did it even reach the bearings? There are also the people that will pump grease into the hub and keep pumping until the seal starts to expel excess grease. At that point the seal has been compromised, trouble is just down the road, around the corner, and over the hill!

The second issue is what Lwwilltravel mentioned. When you get real aggressive, and pump grease into the hub until it is packed, as soon as the hub starts spinning (i.e. rolling down the road) the grease starts heating up. This allows the grease to soften and expand. And that creates a problem. Once it starts to expand the grease has to go somewhere. With the spring loaded cap the spring may compress some and allow for expansion (maybe.) The non-springloaded caps will possibly push themselves off the hub and bounce out into the ditch and weeds never to be seen again.

If the cap of either system doesn’t give, or if you have a weak seal by the inner bearing, the grease will push out there. Ounce the seal has been compromised and grease is coming out, the centrifugal force of the spinning wheel will throw grease outward and there is a good chance the brake drum and then the brakes will be coated and stopping power will be reduced to white knuckles and standing on the brake pedal praying.

This can also be a very real experience by pumping too much grease into the hub zerk as well.

It is a messy job doing it the right way, and don’t buy the cheapest grease you can find. There is grease made exclusively for axles and is well worth it. (Good grease is made to stay tacky and firm when heated up and expansion is reduced.) Also, by packing the grease into the bearings manually, you know each bearing is lubed and ready for a trouble-free trip. A little time and grease goes a long way! And is more satisfying than sitting on the shoulder of the highway waiting for someone to come to your rescue. (Especially if the hub and axle got so hot that it scored either one or both and that means that you are not going anywhere soon.

You don’t have to travel very long to see a trailer parked on the shoulder with either bearing or tire problem and most of these issues are easily avoided with a little time and care.