Red Green

Senior Member

- Joined

- Dec 8, 2020

- Messages

- 185

I have a couple questions for you Leland.

Did you cover the 4x4 underside and backside with flashing like the original build, or did you just leave it painted? I can see where flashing it could protect it, but I can also see where leaving it open and to the air would allow the beam to air/dry?

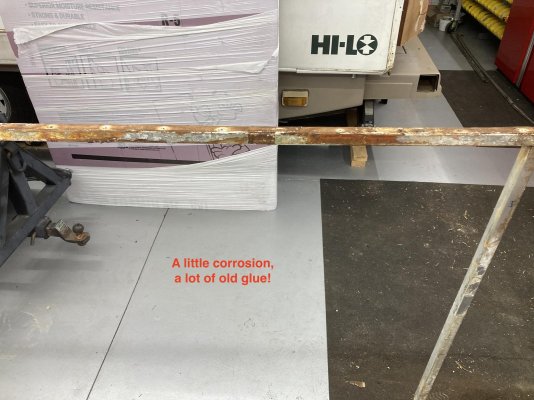

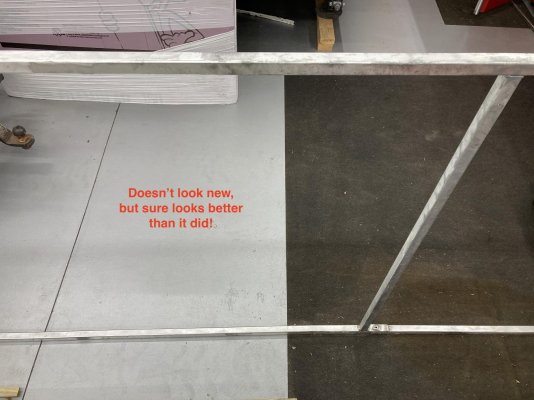

Did you paint the aluminum frame with anything special, or just something basic like Rust-Oleum?

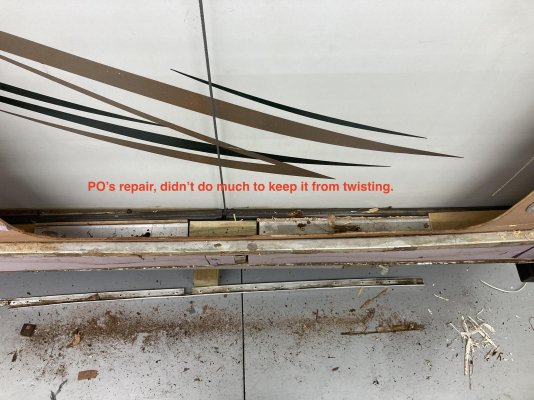

And, the brackets that you placed on the rail to the beam (see picture.) Did you notch the outer luan/plywood panel to keep a flat surface for the fiberglass/Filon? Or did you just go over the top of the brackets with everything?

Speaking of those brackets, would a few screws though the aluminum frame into the beam, both vertically and horizontally hold the frame from twisting in lieu of the brackets? (I can also see where the brackets would be more robust, just thinking out loud.)

Thanks!

Did you cover the 4x4 underside and backside with flashing like the original build, or did you just leave it painted? I can see where flashing it could protect it, but I can also see where leaving it open and to the air would allow the beam to air/dry?

Did you paint the aluminum frame with anything special, or just something basic like Rust-Oleum?

And, the brackets that you placed on the rail to the beam (see picture.) Did you notch the outer luan/plywood panel to keep a flat surface for the fiberglass/Filon? Or did you just go over the top of the brackets with everything?

Speaking of those brackets, would a few screws though the aluminum frame into the beam, both vertically and horizontally hold the frame from twisting in lieu of the brackets? (I can also see where the brackets would be more robust, just thinking out loud.)

Thanks!