The Ohioian

Senior Member

My wife and I bought our trailer in 2010. It's a 1976 17' single axel.

My mom always took me camping with a pop up. I remember her saying after setup i wish we had a hi lo, and every time a brand new one pulled in the campgrounds. our daughter was born in 09 and we quickly realized that my wilderness gear was not going to work for the family. So for the past eight years we have been using the mobile nest(the hi lo)as a cargo trailer putting the gear and the bikes inside. It stinks and leaks like a strainer, it leaks so bad if the morning due is heavy my forehead would get dripped on in the dinette with the kids above me in the loft. We used the trailer every year gutting more and more. To try getting rid of the smell.

My wife (bless her heart) would ask to renovate every year. It was never in the budget or something else would suck the time from my life. I refused to fix anything inside the trailer, instead I worked on road worthy. Breaks,lights,outside aesthetics.

Last year we used the nest 15 Times. Everyone loves it, until they look inside. Ooh they would say. People don't understand why we would camp it. Most rigs we park next to dwarf mine. I never understood going camping with one hundred thousand dollars. The point is to get outside especially today with the kids and the devices.

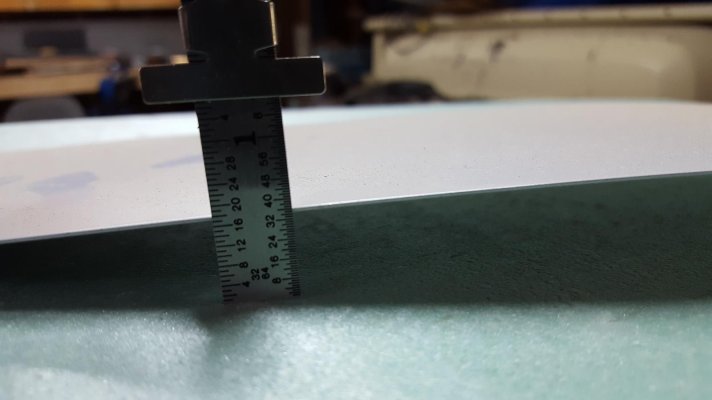

Hi lo's are built panel by panel with the inside paneling as a place holder(The screws will hold just fill the gap.) So if you want it right disassembly should be done. Yes the entire trailer. I filled the gaps with metel shims and spray foam. I wanted as much insulation as possible 2" in the roof was the goal.

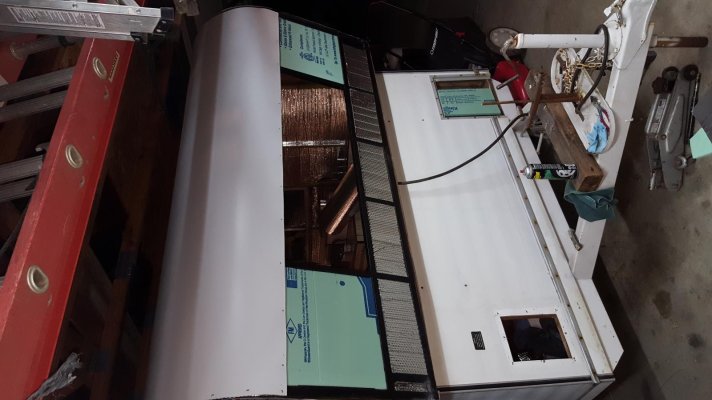

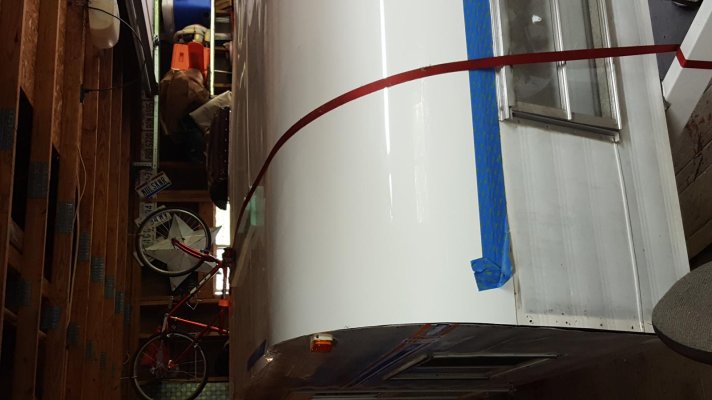

Ripping the nest apart made me question the quality of the trailer.( why not use stainless screws on the exterior baffles me). Anyway we put foam in between the frame and glued them in with silicone. we used 3/4 foam form Lowe's i laminated them together with contact cement and drywall hangers the plastic screw type i did not want anything rusting thru on the headliner just in case something gets wet. Then we stretched the metal on that we bought from Milton valley RV in California. 950.00 with tax and shipping. So we have about 1300.00 in the roof all said and done.

Life is busy. I wanted to start sharing the process with everyone, I just don't have the time to type this. So bear with me on the photos and the process of writing this up.

Not A poet.

My mom always took me camping with a pop up. I remember her saying after setup i wish we had a hi lo, and every time a brand new one pulled in the campgrounds. our daughter was born in 09 and we quickly realized that my wilderness gear was not going to work for the family. So for the past eight years we have been using the mobile nest(the hi lo)as a cargo trailer putting the gear and the bikes inside. It stinks and leaks like a strainer, it leaks so bad if the morning due is heavy my forehead would get dripped on in the dinette with the kids above me in the loft. We used the trailer every year gutting more and more. To try getting rid of the smell.

My wife (bless her heart) would ask to renovate every year. It was never in the budget or something else would suck the time from my life. I refused to fix anything inside the trailer, instead I worked on road worthy. Breaks,lights,outside aesthetics.

Last year we used the nest 15 Times. Everyone loves it, until they look inside. Ooh they would say. People don't understand why we would camp it. Most rigs we park next to dwarf mine. I never understood going camping with one hundred thousand dollars. The point is to get outside especially today with the kids and the devices.

Hi lo's are built panel by panel with the inside paneling as a place holder(The screws will hold just fill the gap.) So if you want it right disassembly should be done. Yes the entire trailer. I filled the gaps with metel shims and spray foam. I wanted as much insulation as possible 2" in the roof was the goal.

Ripping the nest apart made me question the quality of the trailer.( why not use stainless screws on the exterior baffles me). Anyway we put foam in between the frame and glued them in with silicone. we used 3/4 foam form Lowe's i laminated them together with contact cement and drywall hangers the plastic screw type i did not want anything rusting thru on the headliner just in case something gets wet. Then we stretched the metal on that we bought from Milton valley RV in California. 950.00 with tax and shipping. So we have about 1300.00 in the roof all said and done.

Life is busy. I wanted to start sharing the process with everyone, I just don't have the time to type this. So bear with me on the photos and the process of writing this up.

Not A poet.